Standard Features

|

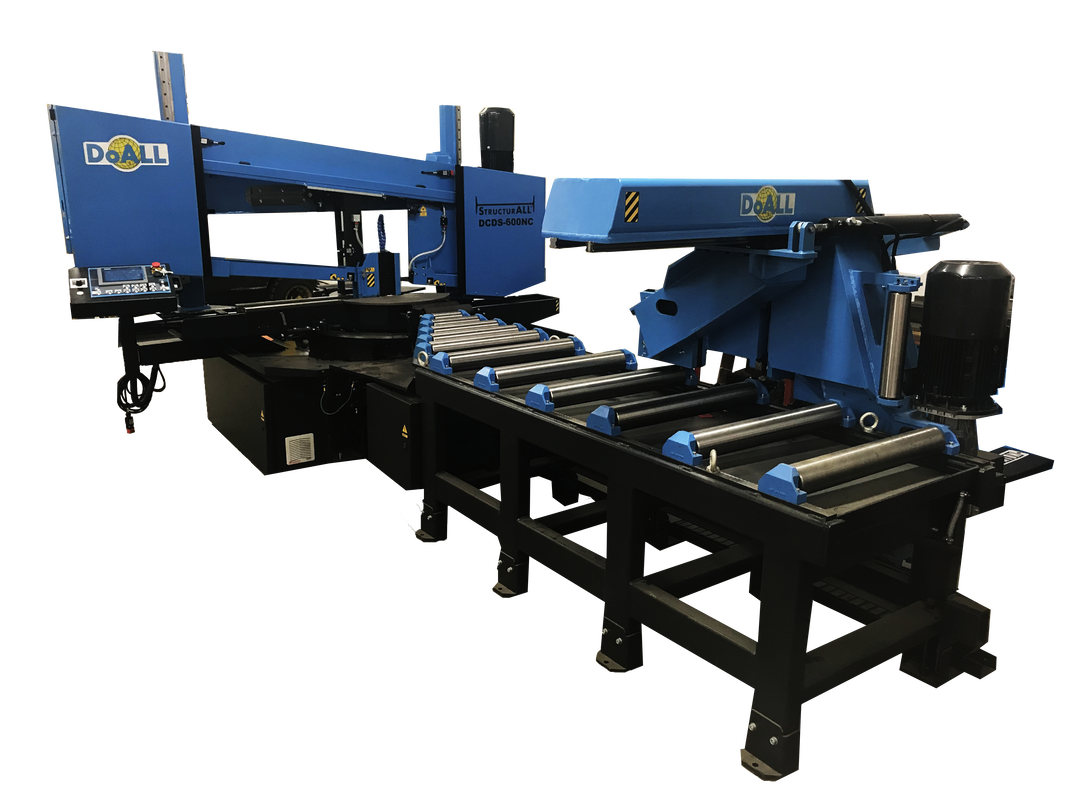

DCDS-600NC

Optional Features

*Please note that some accessories require extra lead time due to factory installation. |

HoursM-F: 8:00am - 4:30pm

|

TelephonePh L1: 909-941-6699

Ph L2: 909-941-9901 |

|